Hydraulic Hose Tractor Supply: Keeping Your Farm Running Smoothly

Farming demands peak performance. Downtime translates directly to lost revenue and a stressful harvest. A significant contributor to unexpected delays? Hydraulic system failures, frequently stemming from neglected or improperly chosen hydraulic hoses and fittings. This guide empowers you to understand and maintain these vital components, ensuring smooth operation and preventing costly breakdowns. We'll cover selecting the right hoses, performing essential maintenance, and identifying potential problems before they escalate. Consider this your tractor's preventative maintenance manual, optimizing efficiency and safeguarding your harvest. For additional resources, check out our helpful guide.

Understanding the Hydraulic System: Your Tractor's Life Blood

Your tractor's hydraulic system is its circulatory system. Hydraulic fluid, pumped through a network of hoses and components, powers everything from lift arms to complex machinery. A leak compromises this system, cutting power and necessitating costly repairs. A reliable hydraulic hose supplier is therefore a crucial resource. These suppliers offer a wide selection of hoses, each engineered to withstand the rigors of farm work.

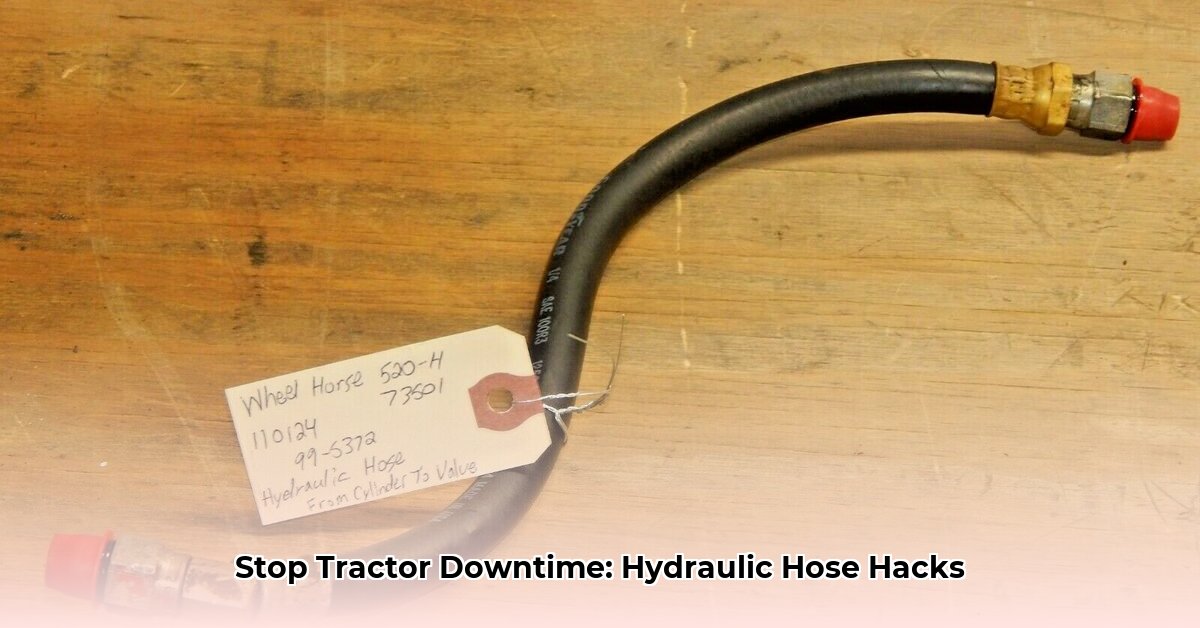

Choosing the Right Hydraulic Hose: A Critical Decision

Selecting the right hydraulic hose is not merely about cost. Several factors demand careful consideration; improper selection leads to premature failure, leakage, equipment damage, and lost productivity. These factors include:

Working Pressure: Hoses possess defined pressure ratings. Consult your tractor's manual to ensure the hose's rating surpasses your system's maximum operating pressure. Underestimation risks catastrophic failure.

Temperature Extremes: Extreme temperatures weaken and damage hoses. Your hydraulic fluid's operating temperature is crucial. Account for your region's climate and your machinery's typical operating temperatures.

Fluid Compatibility: Hydraulic fluids vary. Ensure your chosen hose is compatible with your tractor's fluid. Incompatible hoses degrade and fail prematurely.

Hose Length and Diameter: Precise measurements are critical. Too short a hose risks kinking (restricting flow); too long introduces excess hose prone to damage. The hose diameter must match system requirements for optimal fluid flow.

Here's a comparison table of common hose materials:

| Material | Advantages | Disadvantages |

|---|---|---|

| Rubber | Flexible, relatively inexpensive | Less durable, susceptible to wear and tear |

| Synthetic Rubber | More durable, resistant to many chemicals | Can be more expensive than rubber |

| Steel Braid | High strength, excellent pressure tolerance | Less flexible, heavier, typically the most costly |

The optimal hose material hinges on your specific needs and working conditions. Some environments necessitate the superior strength of steel-braid hoses, while others may suffice with the flexibility and lower cost of rubber or synthetic rubber. Isn't maximizing longevity and minimizing replacements a worthwhile goal?

Regular Maintenance: Proactive Protection

Regular inspections are crucial for preventing hose failures. Addressing small problems before they escalate saves significant time and money. Focus on these areas:

Leaks: Any leak signals trouble. A tiny drip can quickly become a major problem, causing fluid loss and potential equipment damage.

Abrasions and Wear: Check for areas where the hose might rub against other machinery components. These areas are vulnerable to abrasion and should be addressed promptly.

Cracks, Bulges, or Other Damage: These are clear signs of stress and potential failure. Replace any hose exhibiting these signs immediately. Isn't preventing a catastrophic failure better than reacting to one?

Step-by-Step Hose Inspection:

Visual Check: Carefully examine each hose for leaks, abrasions, cracks, bulges, or kinks.

Connection Check: Ensure all connections are secure and leak-free. Tighten loose fittings as needed.

Feel for Heat or Vibration: Unusual heat or vibration may indicate internal problems.

Document and Address: Note any issues and address them promptly. Ignoring small problems can lead to larger issues down the line.

Neglecting hydraulic hose maintenance leads to costly repairs, lost productivity, and potentially unsafe conditions. Proactive inspections are a worthwhile investment – a small amount of effort can prevent significant costs and headaches in the long run.

Repair or Replace: When Professional Help is Needed

Minor abrasions might be addressed with protective sleeves. However, significant damage (cracks, bulges, or leaks) usually requires replacement. Never compromise safety with high-pressure hydraulic systems. A rupture presents a serious danger. When in doubt, consult a qualified mechanic. Isn't safety paramount?

Sustainability and Responsible Disposal: Environmental Stewardship

Sustainable farming extends to responsible material use and disposal. High-quality, durable hoses minimize waste. Many suppliers offer recycling programs for used hydraulic hoses, so inquire about these before disposal to prevent environmental pollution.

Choosing a Reliable Hydraulic Hose Tractor Supply: Partnering for Success

Numerous suppliers offer hydraulic hoses, but choosing a reputable supplier specializing in agricultural hydraulics is essential. Seek a supplier providing expert advice, a wide selection, and prompt service. Thoroughly research your options; the right supplier enhances your operation's efficiency and safety. Investing in optimal hoses and maintenance is an investment in your farm's long-term health and productivity.

How to Choose Sustainable Hydraulic Fittings for Farm Equipment

Key Takeaways:

- Understanding hydraulic system components is vital for preventing costly downtime.

- Selecting fittings based on pressure, temperature, and fluid type is crucial.

- Regular inspection and maintenance extend the lifespan of fittings.

- Sustainable materials minimize environmental impact.

- Proper installation is crucial for preventing failures.

Understanding Your Hydraulic System: The Fundamentals

Your tractor's hydraulic system is vital; fittings are the connectors ensuring smooth and safe fluid flow. Leaks aren't just inconvenient; they represent significant fluid loss, causing environmental damage and necessitating repairs. Downtime equals lost income.

Selecting the Right Fittings: A Practical Guide

Assess Your Needs: Determine your system's operating pressures and temperatures, and the type of hydraulic fluid used. These dictate fitting material and design.

Material Matters: Steel fittings are cost-effective but prone to corrosion. Stainless steel offers superior corrosion resistance, extending lifespan. Brass is less suitable for high pressures or temperatures. Stainless steel is also more easily recyclable.

Fitting Types: Various fitting types exist (JIC, ORFS, BSPP, BSPT). Choose fittings compatible with your tractor's system. Incorrect fittings result in leaks and damage.

Durability and Sustainability: Select fittings from recycled materials whenever possible. Look for manufacturers with sustainable practices. The long-term benefits – reduced environmental impact, longer lifespan, and fewer replacements – outweigh the higher initial cost.

Installation is Key: Proper installation is key. Use the correct tools and follow manufacturer instructions. Incorrectly tightened fittings result in leaks or damage.

Regular Maintenance: Implement a regular inspection schedule. Check for leaks, corrosion, and damage. Tighten fittings as needed (using a torque wrench). Replace worn or damaged components promptly.

Responsible Disposal: Dispose of unusable fittings responsibly. Many suppliers have recycling programs.

Material Comparison Table

| Material | Pressure Resistance | Corrosion Resistance | Temperature Resistance | Sustainability | Cost |

|---|---|---|---|---|---|

| Steel | Medium | Low | Medium | Low | Low |

| Stainless Steel | High | High | High | Medium | Medium |

| Brass | Low | Medium | Medium | Low | Low |

Troubleshooting Common Issues

Leaks are the most common problem. Identify the leak's source (loose fitting, damaged O-ring, or cracked hose). Minor repairs (replacing an O-ring) are often feasible. Consult a mechanic if unsure.